Q: Can you please tell us about your company and the specific problem or challenge that you are addressing?

Q: Tell us about your team and company background?

KINGSTAR is based in Waltham, Massachusetts and is a subsidiary of its parent company, IntervalZero with over 50 employees. IntervalZero’s experience and expertise in embedded technology extends back to 1980 with the founding of its predecessor company, VenturCom. VenturCom developed the technology that led to Microsoft’s first embedded operating system. In 2005, the company was renamed Ardence, Inc., and two years later enterprise software leader Citrix Systems Inc. purchased Ardence, primarily for Ardence’s virtualization technology software. In 2008, Citrix supported a buyout of the embedded technology business by a team of former VenturCom-Ardence-Citrix executives, who formed IntervalZero Inc. Citrix has since been bought out by the CEO of IntervalZero and is now completely privately held.

Corporate Profile:

Website: www.kingstar.com

Social Media:

IntervalZero’s RTX/RTX64 RTOS platform streamlines and simplifies the development of complex systems. By leveraging x86 multi-core technology and symmetric multiprocessing (SMP) functionality, and by extending Microsoft Windows with the RTX real-time extension, the RTX RTOS platform reduces costs, boosts quality and performance, and significantly reduces reliance on proprietary hardware such as DSPs and FPGAs.

KINGSTAR was born out of this RTOS foundation. We simply recognized that industrial motion control and machine vision automation had grown archaic with the limitations of hardware, and that software needed to be the alternative solution – but only if software could provide a comparable alternative that could match or exceed hardware’s performance. The only way software could achieve that was with a real-time operating system. Hence, IntervalZero’s RTX64 became the foundational layer for KINGSTAR’s platform products.

KINGSTAR remains closely tied to IntervalZero through technology, people, and culture. It is still an IntervalZero company, and like IntervalZero, is relentlessly focused on customers that share our pursuit of excellence. We strongly believe that continuous investment in motion control and machine vision software technology is essential for long-term success.

Like IntervalZero, KINGSTAR is based in a strong customer-centric philosophy. Its roots in IntervalZero’s three decades of embedded software innovation, and the proven value of the KINGSTAR real-time motion control and machine vision software, have allowed KINGSTAR to build a global customer base of market-leading OEMs and end users in industrial automation, robotics, semiconductors, manufacturing, textiles, packaging, medical systems, and other industries.

Q: What geographic markets are you focusing on currently?

KINGSTAR is headquartered in Waltham, Massachusetts, USA and also has offices in Taipei, Taiwan; Nice, France; and Munich, Germany. The company is an EtherCAT Technology Group, PLCopen, OPC Foundation, Intel Embedded Alliance and Microsoft Embedded Gold partner and gained Microsoft’s recognition as a leading partner in both North America and EMEA in 2009 – 2012. We currently service all of North America, Europe and APAC, including USA, Canada, UK, Germany, France, China, Japan, Taiwan and South Korea to name a few.

Q: How many users do you have?

Our global customer list consists of well over 200 companies worldwide, including

- 9 of the top 10 Aerospace & Defense companies

- 1 of the top 2 Industrial PLC manufacturers

- 7 of the top 10 Medical Device manufacturers

- 5 of the top 15 Auto Manufacturers

- 1 of the top 5 Test & Measurement companies

- 3 of the top 10 Industrial Control suppliers

- 2 top Full-Flight Simulation companies

- 3 of the top Digital Mixing Consoles companies

- 3 of the top 10 Semi-conductor Equipment makers

- 20+ top machine tool manufacturers

Q: Can you please tell us a little about the market and the market opportunity?

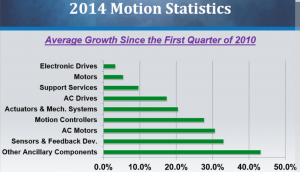

The motion controllers market has been growing at roughly 28% since 2010. It is part of a collective motion control market that represents a $3B opportunity. The mission of KINGSTAR is to produce an equal – or frankly, better – alternative solution to hardware for industrial motion control and machine vision applications. We believe that KINGSTAR can provide companies in the robotics, semiconductors, manufacturing, textiles, packaging, medical devices industries, to name a few, with a cost effective, real-time, PC-based solution that will empower them to build diverse motion control and machine vision applications for real-world situations. These include laser cutting, surface mounters, die bonders, chip probers, CNC milling, etching, conveyors, LED and LCD inspection, and more, all with superior precision performance. KINGSTAR, we believe, will ultimately replace hardware as the de facto solution for industrial machine automation.

Q: Please tell us a little about your technology that drives your platform?

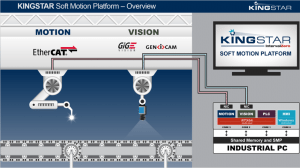

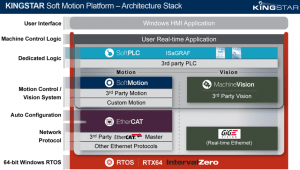

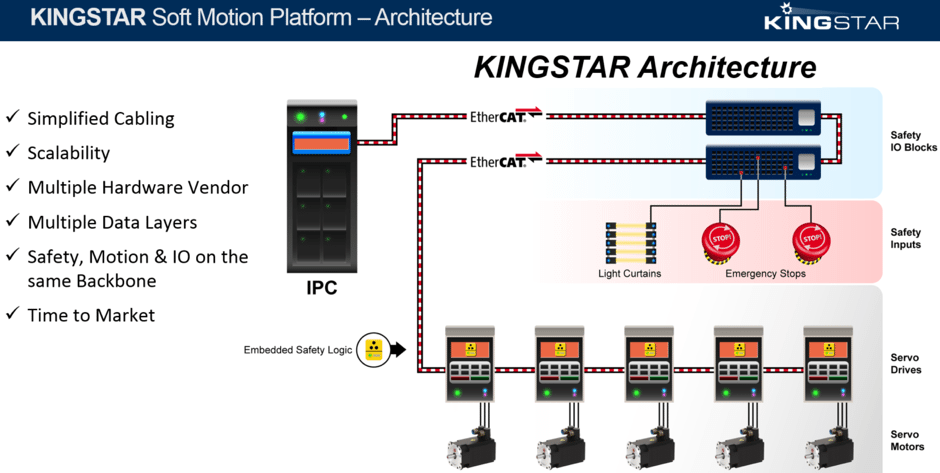

The KINGSTAR Soft Motion Platform is an open and standards-based, integrated platform that enables motion control and machine vision engineers to design, develop, and integrate motion control and machine vision applications with KINGSTAR’s Soft Motion library and software PLC. It is built on the foundation of EtherCAT and a real-time 64-bit Windows operating system, and is a complete platform for functional integration.

Q: What are the key user benefits and features of your platform?

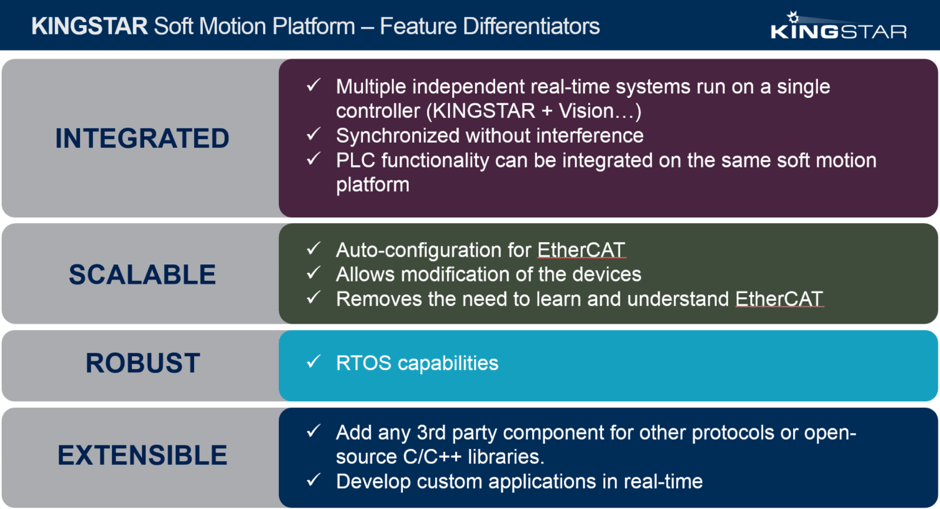

KINGSTAR eliminates the need for proprietary, hardware and individual solutions for industrial machine automation. Through pre-tested, pre-integrated, and best-of-breed software components, KINGSTAR is the only machine automation platform that provides the freedom and flexibility of ‘plug-and-play’ choices, reducing cost by up to half while delivering precision performance and quality. The KINGSTAR Soft Motion Platform consists of the following end-to-end components:

- KINGSTAR Soft Motion provides an integrated environment for consolidated, inexpensive and scalable motion control. Soft Motion runs directly on the PC, uses the NIC card for I/O, and uses the powerful EtherCAT protocol for freedom from proprietary and costly hardware.

- KINGSTAR EtherCAT exposes the real-time interface that allows engineers to integrate their own motion control algorithms or software with an EtherCAT network, providing highly customizable motion control and machine vision with precision performance at an affordable price.

- KINGSTAR Soft PLC, powered by ISaGRAF, delivers application management and deployment that enables complete and consolidated control of assembly lines and machinery.

- KINGSTAR Machine Vision, powered by Matrox, allows engineers to build interactive applications and functions for image capture, processing, analysis, annotation, display, and archiving on GigE Vision® and other camera devices.

- IntervalZero RTX64, the foundation of the KINGSTAR platform, replaces FPGAs and DSPs by transforming Windows into a real-time OS (RTOS), reducing development costs and significantly improving the quality of embedded systems.

Q: What markets will you focus on in the near future and what is your plan to conquer them?

KINGSTAR can benefit virtually any industrial automation shop, including robotics, semiconductors, manufacturing, textiles, packaging and medical industries. The comprehensive list of motion command interfaces coupled with the intuitive function libraries allows for diverse applications, including laser cutting, surface mounters, die bonders, chip probers, CNC vertical and horizontal milling, etching, articulated robot arms, pick-and-place movement, PCB handling, conveyors, LED and LCD inspection and sorting. With KINGSTAR, machine automation manufacturers can benefit from precise positioning and advanced motion and machine vision trajectory control, no matter what the industry.

Q: Who are your competitors?

Our direct competitors are proprietary vendors who provide motion control software and real-time operating systems. Unlike KINGSTAR, to develop on these systems one must buy into their proprietary product and development languages, locking the customer in to their specific toolset. Our top competitors are BECKHOFF’s TwinCAT, CODESYS’ SoftMotion and tenAsys’s INtime.

Basically, the strategy at BECKHOFF, CODESYS and tenAsys is to offer a cheap software motion solution to get the customer started. Once the customer starts developing, he/she figures out that the software version doesn’t offer determinism under 1 millisecond (in one case 500 microseconds). To get to the 125 microsecond level and higher quality, these vendors then try to upsell their own proprietary hardware, which is much more expensive.

At KINGSTAR, the customer has the freedom and flexibility to use the tools of their choice, leveraging open standards and development toolsets along with widely known and used development languages like C++ to support an extensible RTOS with better precision performance quality.

Q: What advantage does your product offer in contrast to your competitors?

These days, almost all industrial automation engineers fall victim to three toolset options to build their applications:

- Proprietary solutions, with vendor lock-in

- Point solutions, buying best-of-breed for every desired component, which can get expensive

- Hardware solutions, which are obscenely expensive

There are pros and cons to each of these options, but none is honestly desired by the engineer; it’s more like “pick-your-poison.” KINGSTAR addresses this problem with an end-to-end, open and standards-based software platform that allows engineers to pick components of their choosing for motion control and machine vision from the ground up. Because it’s built on a hard real-time deterministic 64-bit operating system (RTOS), IntervalZero’s RTX64, all components can either be KINGSTAR’s pre-integrated and pre-tested solutions or ones of the engineer’s own choosing.

Other vendors will offer you things like custom or vendor-built soft motion and PLCs, but the brass tacks come down to having to use their own specific proprietary scripting language that does not give direct access to a general purpose RTOS, but only to their specific RTOS via predetermined and controlled access points. With KINGSTAR, you have a truly transparent open platform that lets you use languages that you already know, like C, C++ and .NET, in order to access ALL platform components and create motion control and machine vision applications.

This flexibility is a real differentiator of the platform approach. Because KINGSTAR is built on the foundation of EtherCAT and a real-time 64-bit Windows operating system, it gives engineers premium precision and performance at half the cost of hardware.

Q: What makes your platform stand out?

The KINGSTAR platform gives you control, autonomy, and flexibility. Let’s say you want to leverage the increasingly popular EtherCAT fieldbus as your industry standard. You have the freedom and flexibility to choose either KINGSTAR’s basic CANopen over EtherCAT, or you can choose an EtherCAT master of your choice like Acontis, Koenig or ESD. Let’s say you want to leverage your own customized soft motion control algorithms and APIs. No problem; you can integrate your own customized solution into EtherCAT or leverage KINGSTAR’s own robust set of Soft Motion Control algorithms.

It doesn’t stop there. What if you wanted to add machine vision-directed motion control? Well, then options like KINGSTAR or Matrox’s Imaging Library are completely available to you. Finally, if you want to complete the full set by leveraging your favorite PLC for HMI, then go right ahead and choose PLCs like ISaGRAF or PHOENIX CONTACT as your application management system. In other words, an open platform empowers customers to have their cake and eat it too: They get the benefit of pre-integration (they do not have to integrate) and all their components are state of the art.

Q: What is your focus for the next 6-12 months?

The strength of a platform is that it can integrate the best-of-breed components for the highest quality and performance. The more components there are in the platform, the stronger the platform is. KINGSTAR is already strong in this regard, and in the future, more and more components can and will be added to this open platform for availability, such as Kinematics (for CNC and Robotics) and Simulation.